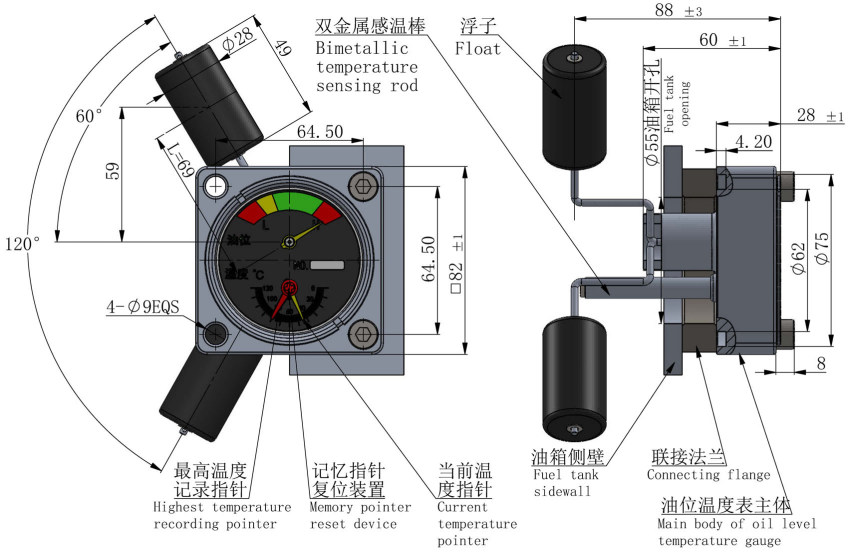

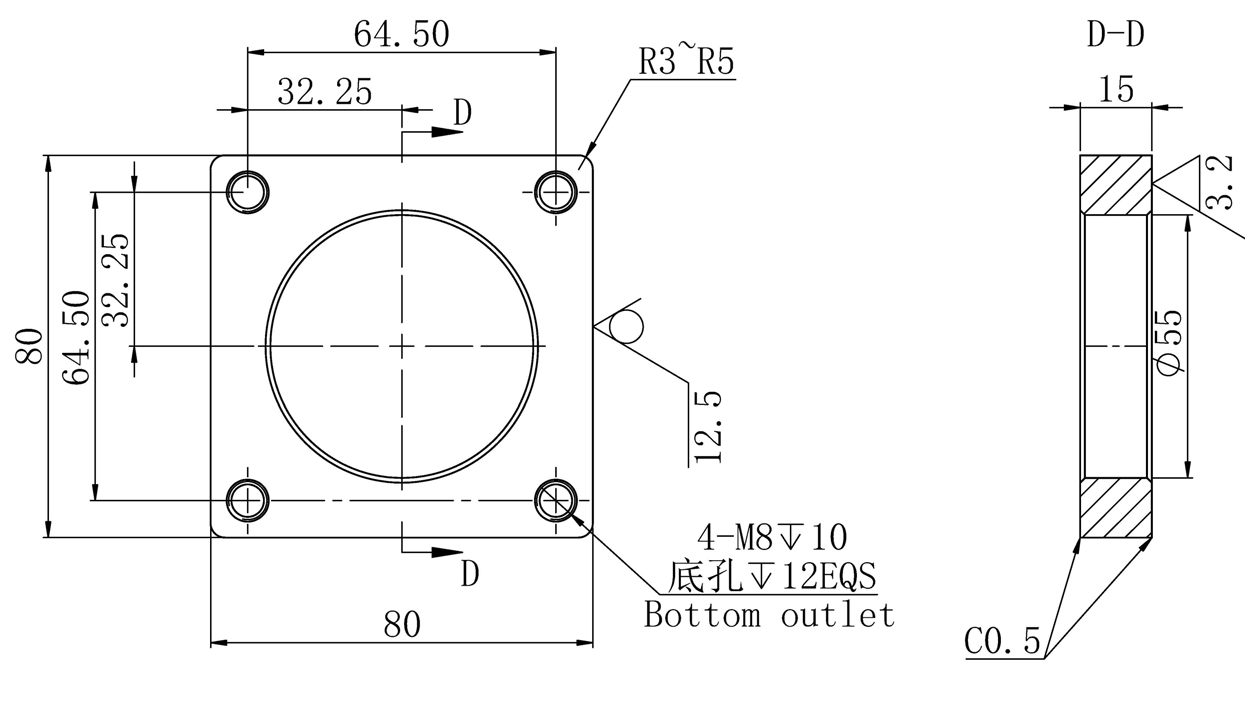

The YWZ transformer integrated oil level temperature gauge is a product that combines the oil level testing device and oil temperature testing device of the transformer oil tank. Its main structure includes: the float part of the oil level gauge, the transmission part, the magnetic coupling, and the indicator part; The bimetallic temperature sensing rod and indicator part of the thermometer. The float part drives the oil level indicator through the transmission part and magnetic coupling, and finally indicates the oil level on the dial through the pointer; The thermometer part converts the temperature changes sensed by the bimetallic temperature sensing rod into the rotation of the pointer and accurately indicates them on the dial, serving the purpose of on-site observation. This product is produced by the company with a body size of 80mm, suitable for small diameter oil storage tanks, box transformers, American style box transformers, and on load switch oil storage tanks.

2.1. Environmental temperature: -45 ℃~+70 ℃, working temperature:- 45℃~+120℃; 2.2. Relative humidity: When the air temperature is 25 ℃, the relative humidity should not exceed 90%.

2.3. The oil temperature should not exceed 120 ℃.

2.4. Places without severe vibrations and bumps.

2.5. Oil level indication error: less than ± 2.5% of the entire disk.

2.6 Sealing performance: 200kPa.

2.7 Protection level: IP55。2

2.8. Long term stability: not less than 10000 cycles.

2.9. Oil temperature measurement range: 0-120 ℃

2.10. Oil temperature indication accuracy: Level 2.5

Precautions

3.1. This oil level temperature gauge is a precision instrument, and all indicators have been calibrated before leaving the factory. If there are any problems, please contact our company in a timely manner; If disassembling and assembling the watch body by oneself, the consequences shall be borne by oneself;

3.2. This product is a precision instrument and should be avoided from severe impact or long-term operation in a severely bumpy environment;

3.3. Avoid severe fluctuations in the measured oil level;

3.4. The oil level section on the dial only indicates the relative position between the pointer and the float. To accurately determine the oil level, it is necessary to calculate based on the position of the float and the length of the gauge stem. Before installing the oil level gauge, the following checks should be carried out:

3.5.1 Check if the pointer movement corresponds to the movement of the float;

3.5.2 Check if the pointer rotates smoothly and flexibly;

3.5.3 Check if the dial glass is well sealed;

YWZ □-□ □

Environmental conditions, special instructions

Specification (outer contour)

Design Number Y:

W

Z:

Y: Oil level gauge; W : thermometer; Z: Pointer type

Example annotation:YWZ2-80TH is the second design, with an outer contour of 80mm and anintegrated oil level temperature gauge suitable for humid and hot zones.

Installation Dimensional Drawing