LD-B10-C220Y series temperature controller of dry transformer (Referred to as temperature controller) is a high performance controller initiated designing specially for users who works in rail transport, station , airport or who has special requirement. The temperature controller has the most comprehensive performance in and abroad and has good EMS and EMI. The C220Y series temperature controller has widely used in Guangzhou Subway, Chengdu Subway, Shenzhen Subway, Nanjing Subway, Shanghai World Expo and Guangzhou University City. The main features as follow: ▲ The protection class is IP54, it can effectively prevent water droplets, dust from entering the controller. ▲ The over-temperature alarm and tripping contacts has high capacity and large power in both AC and DC. ▲ The working state and measured values display more intuitive for using Lcd and Led. ▲ The realtime can be run while powerdown, so could not reset after power down.

Type selection (arbitrary combination of E, F, G/I and C)

Capacity of Control of output : 7A/250VAC; 5A/220VDC (Resistance)

Relative humidity: < 90% (25℃)

Power voltage:220VAC、220VDC、110VDC(+10%,-15%)(Optional) Power frequency: 50HZ or 60HZ (±2HZ)

IEC61000-4:2002 International Standard

GB/T17626-2008 Standard for Electromagnetic Compatibility Test and

Measuring Technology

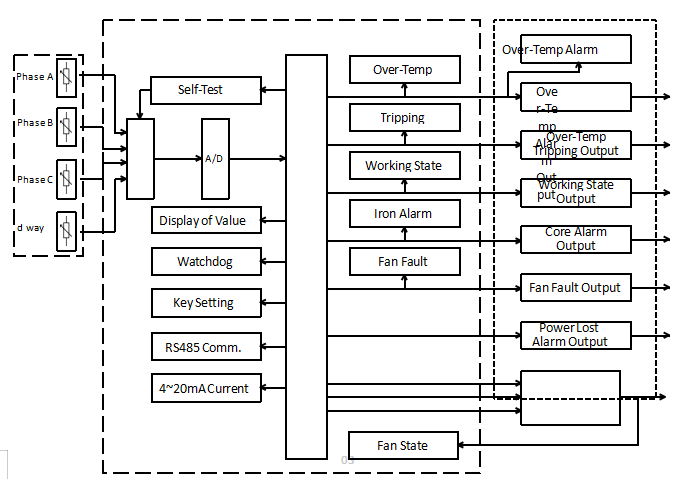

Schematic diagram of controller

Ambient temperature: -25℃~+55℃; Relative humidity: < 95%(25℃);

Power frequency: 50Hz or 60Hz(±2Hz);

Power voltage: AC220V(+10%, -15%);

AC380V(+10%, -15%);

(If there is no special indication when ordering, AC220V shall prevail)

-30.0℃~240.0℃

Grade of accuracy: Grade 1(Grade 0.5 for temperature controller, Grade B for sensor);

Resolution: 0.1℃

≤8W

Capacity of contact of fan: 6A/250VAC (cosΦ=0.4);

Capacity of control output: 5A/250VAC (Resistance); 5A/30VDC

JB/T7631-2016 Electronic Thermo-controllers for Transformers ISO9001:2015 Quality Management Systems-requirements

Type |

Function |

|

LD-B10-C220YI |

Measure and display 4 channels, where CH-A、CH-B、CH-C stand for the 3 phases of the transformer windings, CH-D stands for the transformer core temperature. Display and output selt-testing for open circuit and fault; Display and output over-temperature alarm; Display and output over-temperature tripping; Auto start and stop of Cooling fan and output; Mutual switching between manual and auto control fan; Fan run signal transmition; Digital compensation for each channel; The datas save while powerdown; Timed start and stop fan; Power lost alarm; Fan fault alarm. |

LD-B10-C220YEI |

The same as LD-B10-C220YI, with addition of independent 4-way 4~20mA analogue current output. |

LD-B10-C220YFI |

The same as LD-B10-C220YI, with addition of RS-485/232 serial communications function.(Communication distance is less than 1200 m). |

LD-B10-C220YI+BS |

The same as LD-B10-C220YI , with addition of door contact alarm. |

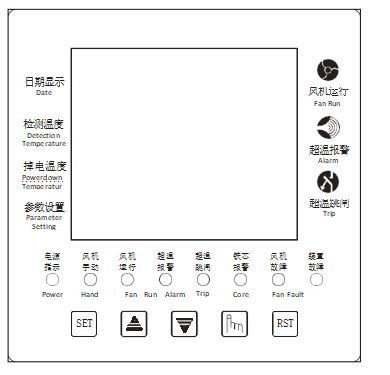

Pannel

Lcd display and indicator light

Lcd Display:Measuring channels, measuring values, parameters and time. Light“Power”:Indication of power supply of controller .

Light“Hand”:Indication of fan operation in manual way. Light“Fan Run”:Indication of fan stop and run state Light“Alarm”:Indication of coil over-emperature alarm. Light“Trip”:Indication of coil over-emperature tripping. Light“Core”:Indication of core over-emperature alarm. Light“Fan Fault”:Indication of fan fault.

Light“Fault”:Indication of controller fault and sensor fault.

Fault Symptoms |

Potential causes |

Remedies |

Display not light after energization. |

Power line not connected properly or low voltage. |

Check for input power. |

“-OP-” blinks in X-phase and fault light is on. |

|

|

“-OH-” blinks in X-phase and fault light is on. |

Temperature out of upper limit of measurement or sensor measuring loop has a higher contact resistance. |

Eliminate wire contact resistance. |

“-OL-” blinks in X-phase and fault light is on. |

Temperature out of lower limit of measurement or sensor measuring loop is short-circuited. |

Check the measuring line of sensor. |

“-Er-” blinks in the temperature controller and fault light is on. |

Internal setting parameter is changed or internal fault of temperature controller |

Contact the manufacturer at once. |

Fan runs of itself before starting temperature is reached. |

|

|

Failure to turn off the fan manually after manual start of fan. |

The measured temperature value is just between the positive and negative backlash values of fan. |

Normal state. |

Three-phase measurement temperature imbalance |

Difference in fixation depth of thermo-resistor. |

Adjust fixed thermal resistance. |