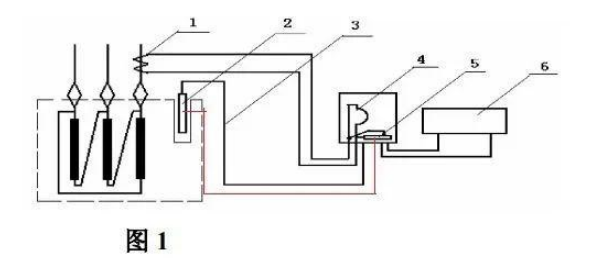

The temperature of the oil and windings inside a Transformer affects the performance and lifespan of the insulation materials, thereby impacting the transformer's lifespan and potentially leading to faults. Therefore, it is necessary to monitor the real-time temperature inside the transformer. Based on the temperature measurement principle, there are three types of thermometers: 1. Mercury thermometer; 2. Pressure thermometer; 3. Platinum resistance thermometer.

|

|

|

|

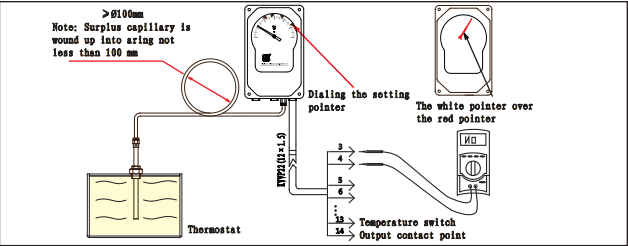

How the measured temperature is used:

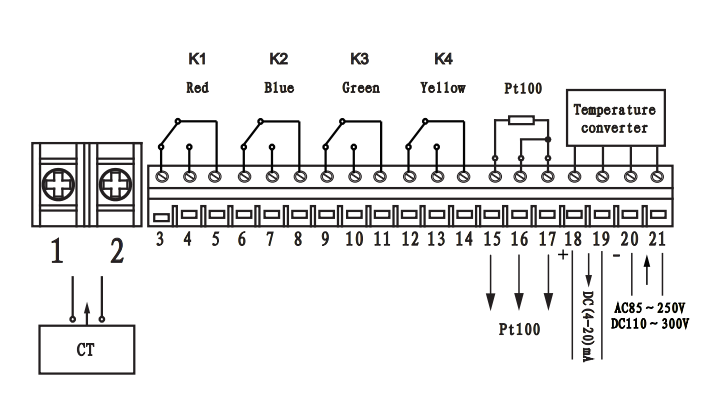

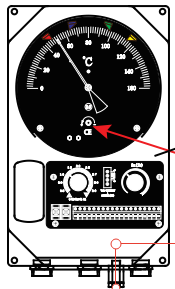

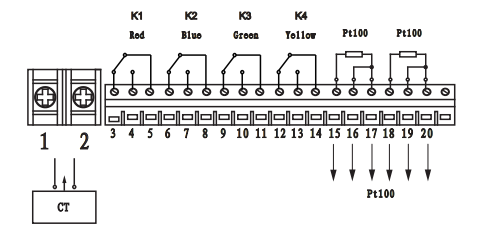

1. Sent to the main meter for real-time pointer display;

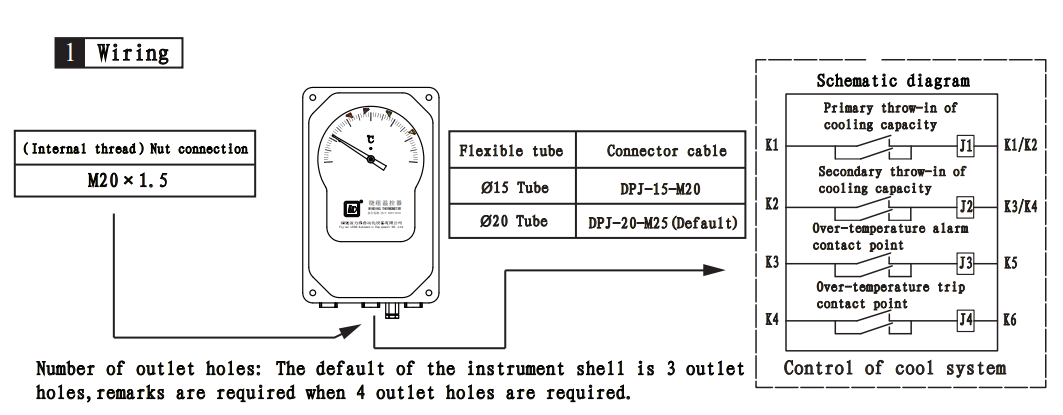

2. Through the meter's auxiliary contacts, control the cooler and send alarm signals;

3. Analog signals are sent to the measurement and control device, displaying the temperature on the monitoring backend. Maintenance personnel handle abnormal temperature conditions according to the manufacturer's instructions and regulations.

|

|

|

|

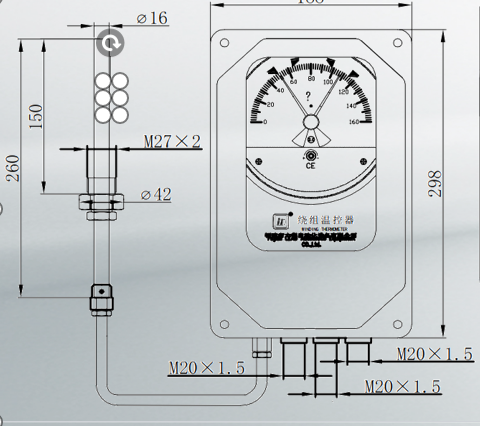

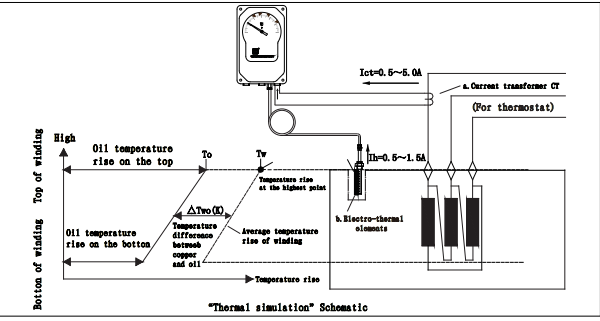

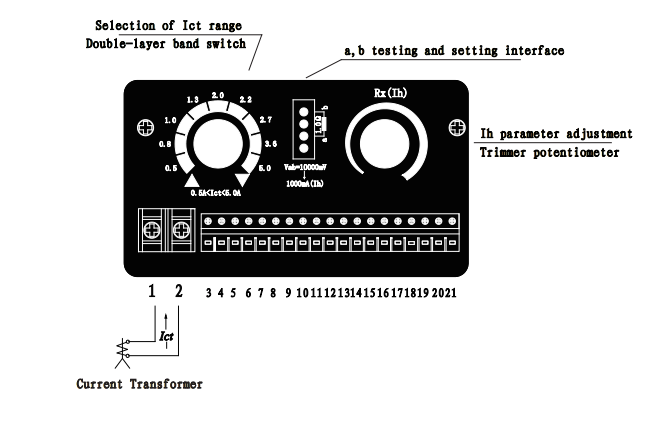

Large transformers, which operate under high voltage and strong magnetic fields, generally use the "pressure thermometer" principle. There are two types of temperature controllers for transformers: oil surface temperature controllers and winding temperature controllers. Their principles and structures differ in one aspect. Here, we will directly introduce the winding temperature controller.